4.8 Google Rating

Supply Chain Issues in the HVAC Industry

The HVAC industry has faced significant supply chain challenges over the past few years. From shortages of critical components to delays in manufacturing, these disruptions have left homeowners and businesses struggling to maintain or replace their HVAC systems. The ongoing global pandemic, combined with geopolitical tensions and labor shortages, continues to affect the availability of HVAC equipment. In particular, the HVAC equipment shortage has impacted everything from residential air conditioning units to industrial systems, creating long wait times for both consumers and contractors.

This blog will dive into the main causes of supply chain issues in the HVAC industry, focusing on how these challenges have affected homeowners, contractors, and major brands like Carrier. We’ll also offer insights into what you can do to mitigate these delays and ensure your HVAC needs are met, even during these difficult times.

Causes of HVAC Supply Chain Disruptions

Several factors have contributed to the HVAC equipment shortage, and understanding these reasons can help homeowners and businesses prepare for delays and price increases.

Material Shortages

The HVAC industry relies heavily on various materials like steel, aluminum, and copper. These metals are essential for producing heat exchangers, coils, and other components. Unfortunately, global shortages of these materials have slowed down production across multiple industries, including HVAC. Furthermore, supply issues with electronic components, like semiconductors, have compounded the problem, as HVAC systems increasingly rely on advanced technologies for efficiency and smart home integration.

Manufacturing Delays

Due to the pandemic and subsequent labor shortages, many HVAC manufacturing facilities have experienced delays. Plants have been forced to shut down temporarily, while others operate at reduced capacity due to social distancing measures and a limited workforce. As a result, production has slowed significantly, contributing to the Carrier HVAC equipment shortage and similar problems across other major brands. Even as factories attempt to return to full production, the backlog of orders and the unpredictable nature of supply lines make it difficult to keep up with demand.

Transportation Bottlenecks

Global transportation disruptions have played a critical role in exacerbating supply chain issues. Shipping delays at major ports, coupled with a shortage of truck drivers, have hindered the timely delivery of HVAC components and finished units. The HVAC equipment that manufacturers manage to produce often faces extended delivery times due to a lack of available freight and other transportation-related challenges.

Increased Demand

While supply chain issues have slowed down production, demand for HVAC equipment has skyrocketed in recent years. As homeowners spend more time indoors and businesses upgrade their ventilation systems for health and safety reasons, the demand for air conditioning and heating systems has surged. This increased demand, coupled with the shortage of available products, has driven up prices and created long wait times for essential equipment.

The Impact on Homeowners and Businesses

The Carrier HVAC equipment shortage and broader supply chain challenges have had a direct impact on homeowners and businesses alike. Many customers are finding that HVAC repairs and replacements take longer than expected due to the unavailability of key components or complete systems. In some cases, contractors are forced to offer temporary solutions or patch jobs until the proper equipment becomes available.

Here are some ways that the HVAC equipment shortage might be affecting you:

Longer Wait Times for Installations and Repairs

Homeowners who need new air conditioning or heating systems are facing delays in getting equipment installed. In some regions, these delays can stretch for weeks or even months. This is particularly problematic during peak seasons, such as the summer or winter, when the need for heating and cooling is most critical.

Higher Costs

Due to the scarcity of HVAC units and parts, prices have surged across the industry. Consumers may find themselves paying more for the same systems they could have purchased at a lower cost just a few years ago. Unfortunately, there’s little relief in sight, as manufacturers pass on the increased costs of materials and labor to the end user.

Limited Selection of Available Equipment

Because of the Carrier HVAC equipment shortage, as well as shortages from other brands, homeowners may not be able to find the exact system they want. Instead, they may be forced to choose from a limited selection of available models, which might not meet their efficiency or performance standards.

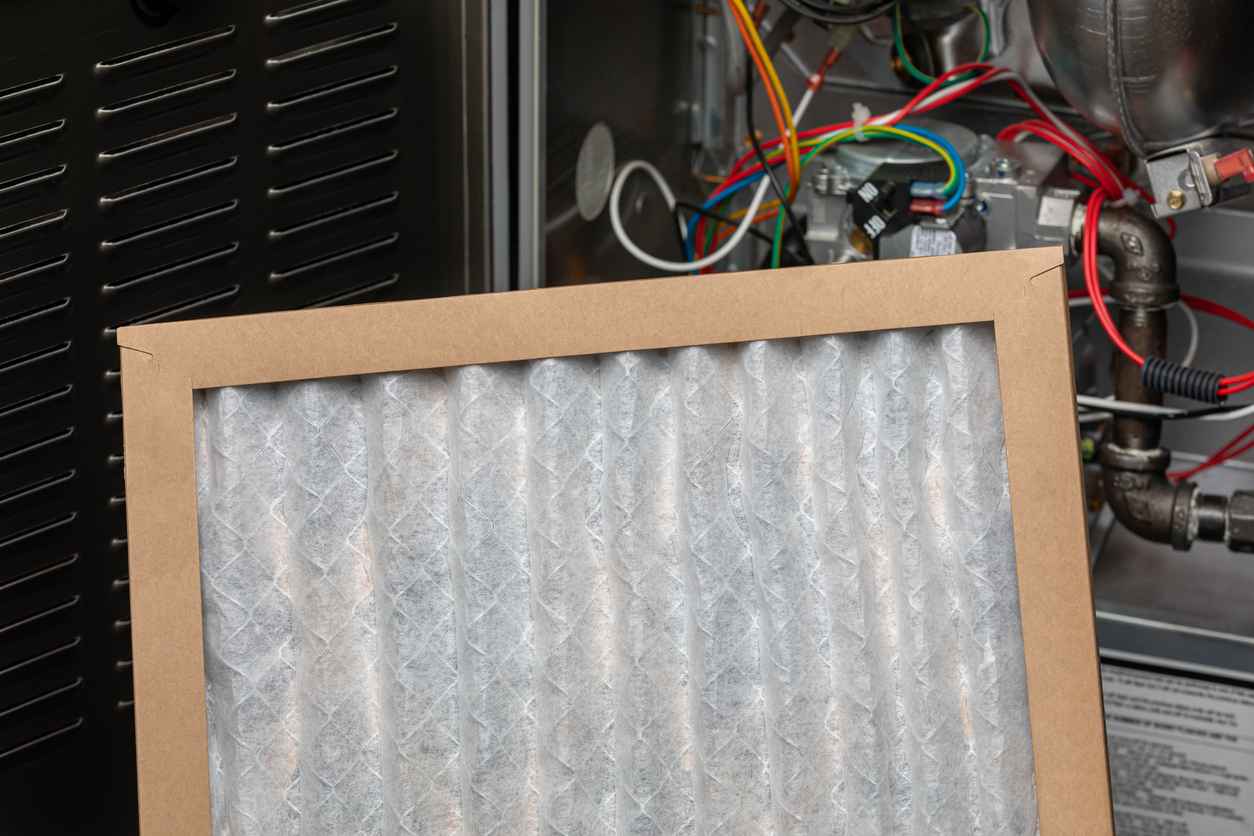

Delayed Maintenance

Routine maintenance tasks, such as replacing air filters or upgrading components, are also affected by supply chain disruptions. HVAC contractors are finding it increasingly difficult to source replacement parts, leading to delays in scheduled maintenance visits. This can result in reduced system performance and increased energy costs for homeowners.

How to Navigate HVAC Supply Chain Challenges

Despite these challenges, there are a few strategies that can help you manage the impact of the HVAC equipment shortage:

Plan Ahead

If you know that your HVAC system is nearing the end of its lifespan, don’t wait until it breaks down to start shopping for a replacement. Proactively scheduling your system replacement during the off-season can give you a better chance of avoiding delays. Speak with a qualified HVAC professional to assess the condition of your system and make a plan for replacement well in advance.

Work with a Reputable HVAC Contractor

Partnering with an experienced HVAC company, such as McCullough Heating & Air Conditioning, can help you navigate the current challenges. Established contractors have strong relationships with manufacturers and can often source equipment more quickly than smaller or less established companies. McCullough Heating & Air Conditioning works closely with suppliers to ensure the best possible outcomes for our customers, even during times of supply chain disruption.

Consider Alternative Solutions

If your preferred brand or model is unavailable due to the Carrier HVAC equipment shortage, consider exploring alternative options. While some units may be in short supply, others might be more readily available. An HVAC professional can help you choose the best alternative system for your home’s needs without compromising on performance or energy efficiency.

Stay Flexible

In times of uncertainty, flexibility is key. Whether it’s selecting a different system or being patient with installation timelines, remaining flexible will help you navigate supply chain issues without compromising the comfort of your home.

Conclusion

The HVAC industry is experiencing unprecedented challenges due to the ongoing supply chain disruptions. From material shortages to transportation delays, the HVAC equipment shortage has made it more difficult for homeowners and businesses to get the systems they need in a timely manner. However, by planning ahead and working with an experienced contractor like McCullough Heating & Air Conditioning, you can overcome these challenges and ensure your home remains comfortable year-round.

Contact McCullough Heating & Air Conditioning today for all your HVAC needs. Our team is here to help you navigate equipment shortages and provide expert guidance on the best heating and cooling solutions for your home. Don’t wait—get in touch with us now to schedule your consultation and stay ahead of the supply chain challenges!

Recent News

Top HVAC Companies in Austin, TX: Looking Beyond Ads & Reviews

What Sun City Homeowners Should Know About HVAC Permit Data & Installations

Free Energy Audits for Westlake Homes: Cut Energy Bills, Boost Comfort & Upgrade Smarter

Is Your Austin Home Using Too Much Energy? Here’s How a Free Energy Audit Can Help You Save Big

Cold Snap Coming? What Austin Homeowners Should Do Now to Prevent Heat Loss and Heating System Failure

Best HVAC Filters for Cedar Fever in Austin